the entire world of manufacturing is consistently evolving, driven by the need for enhanced precision, efficiency, and value-efficiency. One know-how that is certainly swiftly transforming industries is laser welding. As a leading Laser Welding equipment provider, we are witnessing firsthand the profound impact these machines are acquiring on modern production processes. This weblog put up explores the core benefits and benefits of laser welding, demonstrating why it is becoming an indispensable Resource for corporations striving to stay aggressive.

Table of contents:

Introduction to Laser Welding know-how

Advantages of Laser Welders more than Traditional Welding strategies

How Laser Welding equipment make improvements to manufacturing Efficiency

Introduction to Laser Welding technological know-how

Laser welding can be a fusion welding procedure that utilizes a focused laser beam to hitch resources. The substantial concentration of Electricity allows for deep, narrow welds with negligible heat-impacted zones. This exact control minimizes distortion and harm to bordering elements. Unlike classic welding techniques, laser welding can be employed on the wider variety of resources, which include dissimilar metals, and sometimes involves minimal to no filler material. the method is adaptable to automation, allowing for for enhanced velocity and consistency in creation. The Laser Welding equipment provider sector is expanding promptly, driven via the rising desire for this functional technology.

benefits of Laser Welders about regular Welding Methods

as opposed to conventional tactics like MIG or TIG welding, laser welding presents several key benefits. initially, the precision of your laser beam permits significantly smaller and a lot more aesthetically satisfying welds. Second, the heat-afflicted zone is substantially minimized, minimizing distortion and preserving the integrity with the surrounding substance. 3rd, laser welding is considerably faster, bringing about elevated manufacturing throughput. Fourth, it may weld dissimilar metals more correctly, opening up new style and design possibilities. ultimately, laser welding is highly automatable, lessening labor charges and growing regularity. This suite of Positive aspects would make laser welding a persuasive option to regular welding methods for any big selection of programs.

How Laser Welding devices strengthen Production Efficiency

Laser welding drastically improves generation efficiency in numerous methods. The pace and precision of the method let for more quickly welding cycles, leading to bigger output volumes. Automation abilities further more enhance performance by reducing the necessity for guide intervention and minimizing glitches. The slender weld seams involve fewer article-weld finishing, saving time and means. Furthermore, the ability to weld dissimilar metals simplifies producing procedures and decreases the need for numerous signing up for approaches. For example, In line with details from LatheGlobal, their fiber optic, water-cooled laser welding (HW-2000W) machines demonstrates the Superior engineering driving this performance revolution. The trustworthiness and repeatability of laser welding lead to steady solution high quality and cut down scrap rates, more boosting Total efficiency.

In summary, laser welding is revolutionizing present day production by giving unparalleled precision, pace, and efficiency. From aerospace to automotive to electronics, industries are more and more adopting laser welding technologies to achieve a competitive edge. for a Laser Welding Machine provider, we've been dedicated Laser welding to providing cutting-edge answers that empower corporations to remodel their producing processes. in case you want to help your manufacturing capabilities and remain forward in the curve, take into consideration exploring the advantages of laser welding. the long run of producing is below, and It is getting welded with lasers.

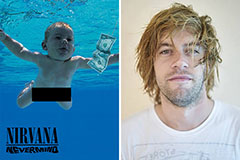

Spencer Elden Then & Now!

Spencer Elden Then & Now! Bradley Pierce Then & Now!

Bradley Pierce Then & Now! Jenna Von Oy Then & Now!

Jenna Von Oy Then & Now! Katey Sagal Then & Now!

Katey Sagal Then & Now! Peter Billingsley Then & Now!

Peter Billingsley Then & Now!